Your Direct Source for Customizable Recycling Bins & Waste Containers

X

SEARCH

View All Products

EXPLORE ALL STATIONS & RECEPTACLESWho we are

Our Vision is a simple one:

Great People Working Together to Create

Positive Change in the World.

What we do

At Busch Systems, our purpose is to lead,

educate, and inspire people to maximize

their environmental and social impact.

Why we do it

Our goal is to lead through innovation so we can

equip you with the tools and resources that will

make a positive impact on our environment.

VOTE EVERYDAY FOR

Certified B Corp

We are proud to be a part of a global movement of people using business as a force for good

TRUSTED BRAND IN RECYCLING

#1 Rated Brand

We are the top rated brand in recycling & waste containers via TrustPilot.

YOU’RE IN GOOD COMPANY

TRUSTED BY OVER 40,000 ORGANIZATIONS

New

Featured

Best Seller

Mosaic Series

Innovative and versatile modular recycling and waste container system!

Check It Out

SHOP THE Mosaic Series

New

Featured

Best Seller

Reflection Series

Durability for outdoor waste collection has never looked better!

Check It Out

SHOP THE Reflection Series

New

Featured

Best Seller

Aspyre Collection

Exceptionally Crafted with Our Customers in Mind.

Check It Out

SHOP THE Aspyre Collection

MAKING RECYCLING SIMPLE FOR ORGANIZATIONS SINCE 1985

What Sets Us Apart

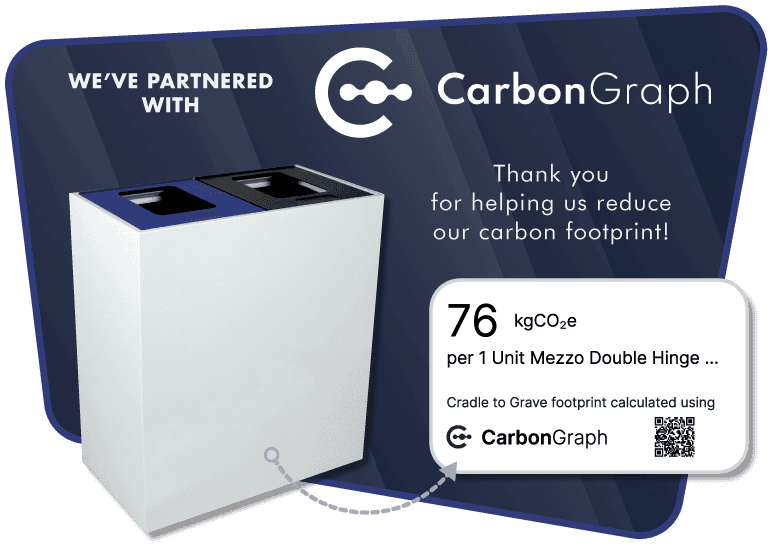

Recycled Content

Our recycling & waste receptacles prioritize sustainability from construction to collection.

Customization

Our bins can be completely personalized to help amplify & standardize your message.

Better Results

Our containers and hands-on strategies are carefully designed to maximize your ROI.

Full-service Offering

Our full-service methodology & support is carefully manufactured to boost your program’s success.

Made in North America

Our products are sustainably manufactured, packed, and shipped from our backyard to yours.

Giving Back

We’re an industry-leader in demonstrating generosity and compassion for the planet and our community.

CRAFTING RECYCLING & WASTE PROGRAMS FOR ALL FIELDS

INDUSTRIES WE’RE PROUD TO SERVE

WHO WE WORK WITH

Architectural Services

When style is your priority but you're tasked with functionality, Busch Systems is here to help. We know that well-designed environments create better behaviors, that’s why we offer a design partnership at the start of your project. Our Designer Series offers a wide variety of containers that complement high-end boardrooms, offices, washrooms, and lobbies. Busch Systems has been passionately designing waste and recycling solutions for over 30 years and with our designer series, we have successfully turned these containers into a functioning piece of décor.

EXPLORE MOREWHO WE WORK WITH

Colleges & Universities

There is no better place to educate and inspire others on diversion best practices than at schools and campuses. From stadiums to dorm rooms, cafeterias to classrooms, Busch Systems has been designing recycle and trash bins for Colleges & Universities for over 30 years! Our experience working with educational facilities has taught us that containers need to be durable, readily available throughout the campus, and customizable.

EXPLORE MOREWHO WE WORK WITH

Elementary & Secondary Schools

Making small changes today for a better tomorrow.

There is no better place to educate and inspire others on diversion best practices than at your elementary or secondary school. From gymnasiums to locker rooms, cafeterias to classrooms, Busch Systems has been designing recycle and trash bins for Elementary & Secondary schools for over 35 years! Our experience working with educational facilities has taught us that containers need to be durable, readily available throughout the school grounds, and most-importantly, customizable to show off your sustainability pride.

EXPLORE MOREWHO WE WORK WITH

Healthcare Facilities

Did you know that of the total amount of waste generated by health-care activities, 85% is general, non-hazardous waste, i.e. waste that is comparable to your domestic waste? The remaining 15% is considered hazardous material that may be infectious, toxic or radioactive.

Hospitals in the US produce more than 5.9 million tons of waste annually and produce 33lbs of medical waste per day per staffed bed. The numbers are staggering but think of these figures as an opportunity to make a significant impact on waste diversion!

— Health Care facilities are loaded with prime locations to collect recyclables and waste, and making sure you have the right containers for each job is step one. Smaller capacity bins should be used at desks and larger capacity bins should be used in high traffic areas. Custom signage and label options can educate staff, patients, and visitors on your recycling program while ensuring that material is sorted correctly.

EXPLORE MOREWHO WE WORK WITH

Resorts

Our experience working with hotels and resorts has taught us two things. 1. Hotels & Resorts generate more waste than most realize. The average hotel guest creates about 2.2 lbs of waste per stay and more than half of it is paper, plastic and cardboard. 2. Containers need to be durable and practical for everyday use, yet aesthetically pleasing to suit each hotels’ unique décor. Hotel operators should consider implementing a proper recycling & waste program to maximize their ROI on removal.

EXPLORE MOREWHO WE WORK WITH

Janitorial Services

Litter, apart from being aesthetically unappealing, it has direct financial, environmental and health consequences to individuals, organizations and societies at large. In a 2009 study, Keep America Beautiful reported that U.S taxpayers spent nearly $11 billion cleaning up litter across the country.

Here at Busch Systems, we offer a variety of cost-effective indoor and outdoor waste receptacles suitable for every industry. These garbage cans are designed to reduce litter and maximize servicing efficiencies so you can spend less time worrying about refuse collection and more time saving money with wholesale commercial trash cans from Busch Systems.

WHO WE WORK WITH

Parks & Rec

A nice walk in the park with the perfect sundae can quickly lead to hundreds of plastic and paper cups and spoons in all the wrong places. The right waste and recycling containers play an important role in keeping your community free from litter. Mass recycling and waste collection programs are a huge responsibility, but park goers are counting on you to provide a safe and clean environment for them and their families. At Busch Systems we offer a complete assortment of indoor and outdoor containers, designed to stand the test of time in these environments. From parks to streets, bus stops to trails and community centers, we’ll bring your community a sense of sustainability pride.

EXPLORE MOREWHO WE WORK WITH

Corporate Offices

Did you know that on average, people now spend approximately 13 years of their lives at work? This means there’s an incredible opportunity and a need to collect recyclables in the workplace. Busch Systems offers an extensive line of office recycling bins in all sorts of sizes and materials that are designed for boardrooms, offices, lobbies, mezzanines, hallways, bathrooms and anywhere else centralized or personal waste collection is needed. We offer an entire spectrum of products from designer to industrial use, to ensure your office is primed for waste collection success.

Employees are highly motivated to work for companies that are aligned with their values and authentically “walk the talk”. Start walking by building an exceptional recycling program, with highly-customizable, designer recycling & waste stations from Busch Systems.

Office recycling has a host of advantages. For many companies, the ability to save money through recycling in the workplace is a significant incentive.

EXPLORE MOREWHO WE WORK WITH

Retail Stores

Go beyond consumers’ higher standards & build brand loyalty.

Consumers are highly motivated to associate with companies that are aligned with their values and authentically “walk the talk”. Start walking with highly customizable recycling & waste stations from Busch Systems.

Retail stores generate a lot of waste, much of which can be recycled. Excessive packaging, including corrugated cardboard and shrink wrap can be efficiently recycled and even generate significant cost savings.

54% in the U.S. and 45% in Canada consider retailers a key source for learning about recycling programs. Consumer support of product recycling is heavily influenced by three key factors: the mode of product collection; how accessible the collection program is for consumers; and their general awareness of take back programs.

Talk to our experts today about how we can help you start a successful recycling & waste collection program for your retail environment.

Let’s build a successful retail recycling program, together.

EXPLORE MOREWHO WE WORK WITH

Amusement Parks & Arcades

Tourism is an important part of every community, and a fantastic opportunity to flex your waste diversion muscle. With Busch Systems in the mix, it’s the best time to make your recycling and waste collection a part of the overall experience. With the right bins and waste management systems, you give visitors at major attractions, the power to make a positive impact on the environment. Whether it’s a museum, an aquarium, a park or the zoo, we have the recycling and waste solutions just for you. Our containers are also customizable to your branding needs. We provide temporary or permanent, indoor or outdoor, recycling and waste bins to help you succeed with waste collection in high traffic areas.

EXPLORE MOREWHO WE WORK WITH

Restaurants

In places like food courts, unclear signage, inconsistent recycling rules and hurried customers can all work against your recycling and waste collection programs. Choosing the wrong waste containers can lead to food on the floor, gunk on the lid that nobody wants to touch, a complete nightmare. Improve your collection rates and reduce contamination with a Busch Systems container today.

From restaurants to food courts and larger events with food service, we have the right recycling and waste collection solution for you. Our food service solutions cater to food waste, organics, recyclables, tray collection, with clear signage and easy servicing access. These are the bins we recommend for high traffic areas with. If you're looking for something a little different, feel free to contact us and we'll find the right container for you and your program!

EXPLORE MOREWHO WE WORK WITH

Sports Stadiums

As far back as 2013, it was estimated that over 17 million people attended professional league games and over 48 million attended college matches — that adds up to over 65 million fans consuming and discarding waste … about 20,000 tons annually. Simply put, high traffic areas require high capacity waste and recycling stations.

For Stadiums and Convention Centers, be sure to choose containers that are durable, highly functional and the right capacity for the job at hand. Rotationally molded products are also built to last! This means they will not rust or dent and can withstand the day to day use and misuse your visitors will hand out.

EXPLORE MOREArchitectural Services

Colleges & Universities

Elementary & Secondary Schools

Healthcare Facilities

Resorts

Janitorial Services

Parks & Rec

Corporate Offices

Retail Stores

Amusement Parks & Arcades

Restaurants

Sports Stadiums

RECYCLING, WASTE, & ORGANICS SOLUTIONS FOR OVER 50 INDUSTRIES!

WHAT’S NEW AT BUSCH SYSTEMS

Here’s what we’ve been up to

Webinar Recap: Scope 3 Inventory: When Assumptions Meet Data

Scope 3 Inventory: When Assumptions Meet Data Original Air Date: Tuesday, April 23, 2024 @ 1:00pm ET Description: The goods and services that universities, government agencies and other large organizations purchase as part of their regular operations can add up to a significant percentage of their carbon footprint. Like other scope 3 emissions, however, it’s traditionally been very...

Earth Day 2024

Earth Day - once a year, in those countries that recognize it, we all do our best to be a little greener; from cleaning up litter and riding a bike to work, to sorting recyclables and turning off the lights, we all try and do our part. But why is there an "Earth Day"? Where and when did it start and what do we do here at Busch Systems beyond this single day to try and keep things just that much greener? Where It All Started To explore when Earth Day started, we need to take a quick look as to why it started. A key contributor to life as we know it today was that...

An Earth Month Update from our Junior Ambassador, Ryan Hickman!

Earth Month is a time to raise awareness around the issues that affect our planet and those who are working diligently to help protect it With this special time of year, we thought it was a good time to catch up with our Junior Ambassador, Ryan Hickman! Between working through his first year of high school and keeping up with his recycling efforts, Ryan is a busy guy, but as enthusiastic as ever about the effort we need to make to help our planet. *** How has the first year of high school been so far?! So far so good! The homework is...

B-Corp Champions Retreat Recap!

Two Busch Systems employees - Marissa and Steph - had the opportunity to attend B-Lab's semi-annual Champions Retreat: RESTORE in March 2024 as part of B-Corp Month. Here is a recap of their week spent with other B-Corporation Champions & leaders! Plenary & Keynotes - Wed March 20th The first full day of the B-Corp Conference was filled with large-group plenary sessions and keynote presentations. And let us tell you - being a single room filled with over 700 B-Corp representatives and hopefuls was a powerful...