Your Direct Source for Customizable Recycling Bins & Waste Containers

X

SEARCH

We are dedicated to offering the most innovative

and customizable recycling & waste bins on the planet

to our valued customers. Forward thinking in the collection

industry is paramount to achieving environmental

sustainability and zero waste.

Have a suggestion for a new container? Take our survey!

How we build our containers

Each waste or recycling container that’s designed at Busch Systems starts with an idea generated from the 30 years of industry experience and/or collaboration with a customer to solve an outstanding issue.

From there, our Research & Development team drafts up CAD drawings to bring to their creative ingenuity to life. Once the specifications are met, the R&D team gets in touch with our numerous eco-conscious vendors to gather the most durable, sustainable and recyclable materials available and the first container mold is created. This is when the R&D team goes back and forth with some of our valued customers and distributors to gather opinions on design, usability and durability. When everyone is happy, then the fun part begins.

We subject Busch Systems bins to numerous stress tests, such as tossing our containers off buildings and cranes and into freezers set to -31 F (although it isn’t necessary; we can just leave them outside where we live to achieve the same temperatures)–all to ensure they’re built to last. After they’ve passed these tests with flying colors, the bins get some final aesthetically pleasing touches and they’re ready to help your program improve mass collection efficiency.

“Companies need to innovate to survive and super innovative companies are the ones that thrive! Everyday, the people at Busch Systems do an awesome job but we encourage our team to pay attention to what causes aggravation, costs time, what could be done better and to look at our products and processes from a customer’s point of view. Innovation is something that we’ve built into our daily work life so we can be one of the super companies that thrive for years to come.”

– CRAIG BUSCH, PRESIDENT & CEO

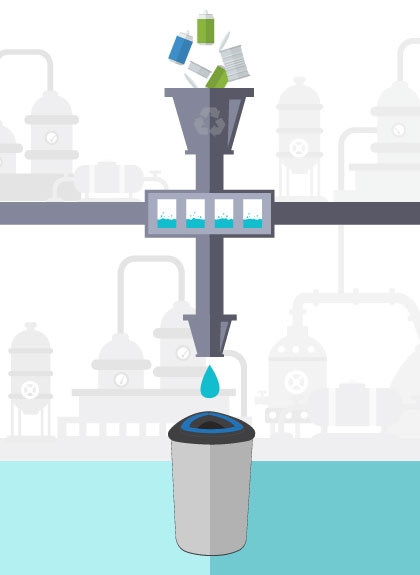

Our Recycled Content

The amount of recycled content used in our containers is extremely important to our overall company goals of helping ourselves and our customers achieve sustainability.

While some of our containers use up to 99% recycled content and most containers have at least 65% recycled content, the minimum standard we have set for our containers is 25%. Every year, we look to improve our minimum standard and you can watch our progress on our sustainability page to see how well we’re doing!

The majority of the recycled content used is recycled waste and recycling containers from existing curbside and other programs (Post Consumer) and the balance is Post Industrial. While the durability of our recycling bins is consistent, the type of recycled material we use for our recycling containers varies. To ensure we are environmentally friendly, we use as much coffee packaging, potato chip bags, retired old recycling bins, scrap material from other facilities and any other recycled plastics we are able to source.

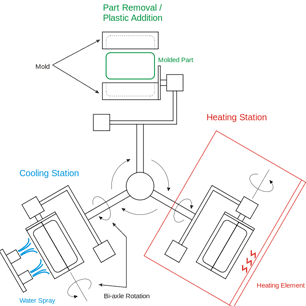

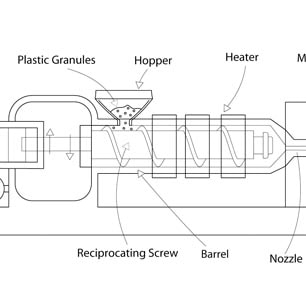

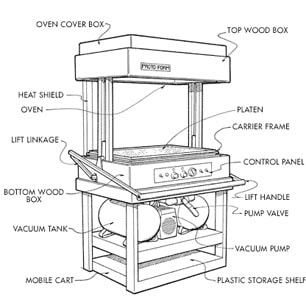

Techniques of creating recycling and waste bins

There are numerous ways to creating the perfect Busch Systems recycling and waste container and we like to use all of them! Certain techniques, such as rotational moulding, have the benefit of creating extremely durable containers most often designed for the outdoors. Injection moulding on the other hand, which is still incredibly durable, is most beneficial for larger runs of smaller containers such as our Kitchen Composters.

The best part about the following techniques is they all allow for maximum recycled content in our recycling and waste containers. If they didn’t, we wouldn’t be using them! Our R&D team works meticulously to choose the right technique for each new product they design. Read on to learn more about these techniques!

Recycling & Waste Bin Customization

And its importance to achieving zero waste

Well-designed environments create better behaviors. A combination of a beautifully designed space coupled with easily accessible, properly labeled and centrally located recycling bins equals a win for sustainability.

Numerous studies regarding recycling and waste communication all come to the same conclusion that signage, colors and labeling are primary to reducing cross-contamination between recycling and waste streams. This reduction in cross-contamination increases efficiency and therefore increases your program’s recycling and landfill diversion rates.

Visit our Customize Gallery